LOTAR Electrical Harness Workgroup

Goals and Objectives

The objective of the Electrical Harness Working Group (WG), much like the objective of the LOTAR Project Objective is to develop, publish and maintain standards designed to provide the capability to archive and retrieve Electrical harnesses information in a standard neutral form that can be read and reused throughout the product lifecycle, independent of changes in the IT application environment originally used for creation

The specific goal of the Electrical Harness Workgroup is focused on the long term preservation of the digital electrical harness models for the design, manufacturing and support.

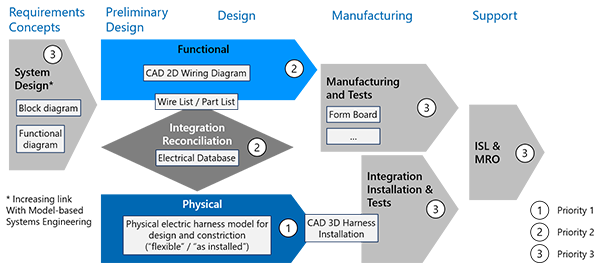

Based on a generic process of development of electrical harnesses, the following picture describes the main categories of electrical harness information to be created in the Aerospace and Defence industry. It allows also to represent the current priorities of development of the LOTAR 4xx standards:

The current main focus of LOTAR 4xx standards (in development) is physical electrical harness data (P1 priority).

Associated LOTAR use cases

The LOTAR standards of the family 4xx will answer to the following use cases (in development)

| Name (proposal) | Status | Priority |

|---|---|---|

| LOTAR of Elec. Harness for Design & Construction for Certification | Agreed | P1 |

| LOTAR of Elec. Harness for Design & Construction for Reuse / Modification | Agreed | P1 |

| LOTAR of Elec. Harness for Design & Construction for Visualization | Agreed | P1 |

| LOTAR of Elec. Harness for Design & Construction for Support in Operation | Agreed | P1 |

| LOTAR of CAD 3D Electrical Harness Installation for Certification | Agreed | P2 |

| LOTAR of CAD 3D Electrical Harness Installation for Visualization | Agreed | P2 |

| LOTAR of CAD Form Board for Visualization | TBD | P3 |

| LOTAR of CAD Form Board for Reuse / Modification | TBD | P3 |

| LOTAR of CAD 2D Wiring Diagram for Consultation | TBD | P4 |

| LOTAR of CAD 2D Wiring Diagram for Reuse / Modification | TBD | P4 |

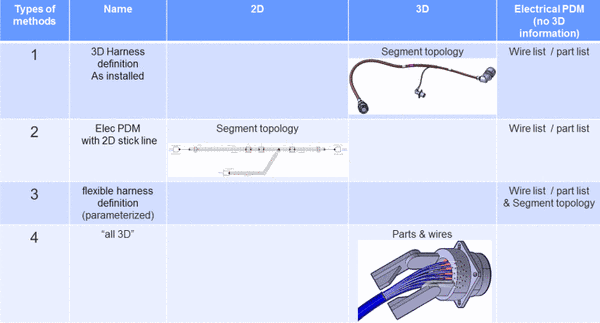

The use cases related to electrical harness for design & construction cover the different methods used by the aerospace or automotive companies for electrical harness design (see following figure).

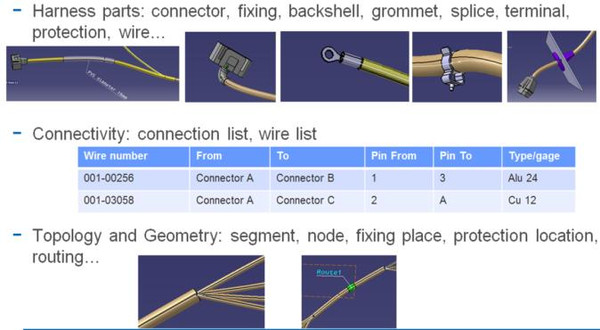

The illustration hereafter gives an overview of the main entities of electrical harness for design and construction.

LOTAR test cases

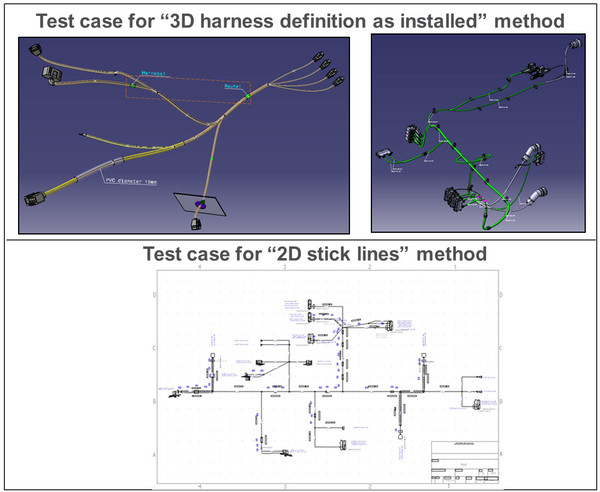

One main task of the working group is the creation of representative test cases illustrating the essential information of electrical harness for design and construction (for example, in order to prepare AP242 Ed.2). See illustration hereafter:

List of LOTAR standards of the Electrical Harness family 4xx.

The planned NAS / EN 9300-4xx standards for the Long Term Preservation of electrical harness information are the following:

| Part | Title (under review) | Planned Ballot date |

|---|---|---|

| 400 | Fundamental and concepts for Long Term Archiving & Retrieval of electrical harness information | 2024 |

| 410 | Long Term Archiving and Retrieval of physical electrical harness for design and construction | 2024 |

| 420 | Long Term Archiving and Retrieval of CAD 3D electrical harness installation | 2025 |

Associated ISO 10303 referenced Information model

- LOTAR standards do not define specific information models for Long Term preservation of CAD and PDM information models. They rely closely on the ISO 10303 Application Protocols, based on the modular architecture, which ensures the consistency of the information models subsets, common to several ISO 10303 standards.

- In this perspective, the LOTAR “Electrical Harness” WG has contributed to the business requirements and use cases for the STEP AP 242 edition 2 project; this Application Protocol includes the information model for electrical harness design.

Resulting planning

Way of working – meetings and teleconferences

- The Electrical harness Working Group holds biweekly WebEx/Teleconf meetings usually on Tuesday from 16:00 – 17:00 (European Central Time), 10:00am– 11:00am (US East Coast time)

- Specific session of the Electrical harness WG during the 4 LOTAR annual Workshops

Accomplishments

- The Electrical harness Working Group was created in February 2012.

- Start of description of the content of the parts 400 and 410 (preliminary draft)

- Definition of use cases for the Long Term Archiving and Retrieval of Electrical Harness data.

- Preparation of test cases for LT preservation of CAD 3D physical electrical harness definition

- Analysis of the glossaries and of the existing standards relation to interoperability of electrical harness design (STEP AP 210, VDA VEC specification, …).

- Start of coordination with other standardization projects related to electrical harness

- Draft list of essential information for electrical harness design & construction

- Contributions to STEP AP242 edition 2 standard through:

- A&D business requirements

- Test cases

- Vocabulary

- Tutorial

- Contribution to EWIS Interoperability Forum with LOTAR specific requirements

Related standardization projects

- EWIS-IF – https://www.cax-if.org/ewis/ewis_introduction.php

- STEP AP210

- STEP AP239

- STEP AP242 – www.ap242.org

- VDA VEC specification – https://ecad-wiki.prostep.org/specifications/vec/

- IEC 60050 – www.electropedia.org

Contacts

Please use the contact form to get in touch with us if you would like more information about the team, workgroup activities and output, or discuss participating in the topic. The team co-chairs are:

Workgroup Leader Europe

N.N.

Contact for Information Europe

Bernd Feldvoss

Airbus

Workgroup Leader Americas

Dan Ganser

Gulfstream