Technical & IT Background

Infinite migration loop vs. neutral data format & standardized processes

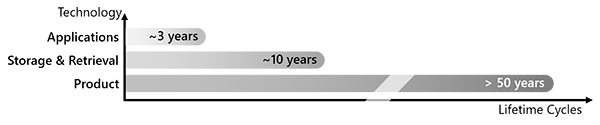

The life cycle of applications and storage technologies hast to be considered by setting up a long term archiving and retrieval standard. Approximately every three years a change in the application technology and every ten years in the technology of storage and retrieval happen. In comparison with an archiving period of fifty up to one hundred years in the aerospace and defense industry the technology life cycle plays a major role.

So far long term archiving of CAD data has meant archiving of 2D drawings as paper drawings, digital images (e.g. as TIFF), paper or aperture cars documents. The continuous development of technical product documentation leads to a change of methods and tools, which are used for design, manufacturing, customer support and archiving. The history of changes for each method is categorized and listed within four main categories:

- before 1980: Mainly manual paper drawings and a minor number of 2D CAD drawings;

- between 1980-1995: Mainly 2D CAD drawings, a minor number of manual paper drawings and additionally 3D surface CAD design;

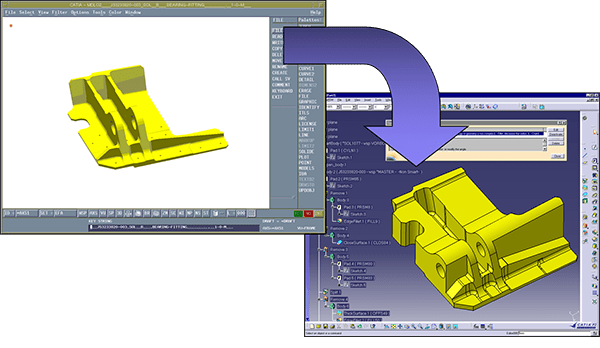

- As from 1995-2006: The usage of 3D solid & assembly CAD design, generated 2D drawings from 3D master models are used;

- afterwards the usage of 3D solid & assemblies with extended GD&T design information might be implemented

The integration of 3D Technologies and GD&T will become an important topic along the complete product documentation lifecycle of design, manufacturing, customer support and long term archiving.

The changes of technical product documentation are closely correlated with the development and releases of new generations of CAD systems. New releases of CAD systems offering new functionalities are now commonly used.

The current situation is characterized by a large number of 3D geometric models, which are kept write protected in databases in their native formats. With the continuing change of CAD technology, this data should be checked and migrated regularly in order to conserve the required geometric model quality. After each migration the native formatted data shall be checked for consistency and completeness. There is no guarantee that the data has not changed after the first release process. A conversion of the native product data into a more stable format is essential.

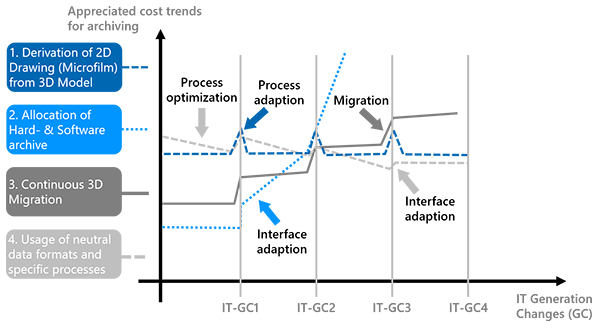

All in all the data conversion into an open and standardized format following an also open and standardized process model is seen as the only efficient solution by meeting various use cases. From this point of view, archiving becomes much more than just safe storage; it is the substantial and operative support for all future engineering activities. In comparison to alternatives e.g. 2D drawings archived on microfilm or continuously 3D conversion it is less resource intensive, enables independence from IT-vendors, allows traceability of changes of data model and guarantees a consistently retrievable data basis.